Iron Plate Conveyor Belts

Plate link conveyor belts, also known as slat conveyor belts or chain plate conveyor belts, are a type of conveyor belt system that uses metal plates connected together in a chain-like pattern to transport materials. These belts are commonly used in food processing, pharmaceuticals, automotive manufacturing and packaging. The metal plates are typically made from stainless steel, carbon steel, or galvanized steel, which ensures durability and corrosion resistance. The plates are connected together using hinge pins or rods, allowing for flexibility and smooth movement along the conveyor system.

These belts are known for their high load capacity, smooth operation, and easy maintenance. They are ideal for transporting materials such as glass bottles, cans, boxes, and pallets. Plate link conveyor belts are also capable of handling inclines, declines, and curves, making them versatile for various manufacturing processes.

As a leading manufacturer of plate link conveyor belts, we offer a wide range of customization options, including various plate sizes, hinge designs, pitch, material and surface coatings, to meet customers specific application requirements.

Overall, plate link conveyor belts offer a reliable, durable and cost-efficient solution for moving materials in industrial applications.

Advantages

① Plate belt is made of metal plate, which can load heavy duty products.

② The baffles can be added onto the belt for convenient sorting and conveying.

③ Can adding side guards to prevent products from spillage.

④ Curved perforated plate conveyor belt is available to suit more applications and equipment.

⑤ Suitable for arduous engineering processes such as press work, die-casting and forging.

⑥ Self- supporting structure for large widths without supports.

⑦ Smooth, flat, continuous surface for stable product transport.

⑧ Resistant to corrosion, wear and high temperatures(-30ºC to +600ºC), Ideal for harsh environments.

⑨ High durability and longevity.

⑩ Low maintenance requirements, easy to clean and install.

Applications

Plate conveyor belts are well suited to drying processes. The self-supporting structure of these belts means they can be used over large widths without support. Perforations allow the opening in the belt to vary from zero to very large. Chain-driven plate belts can be fitted with edge plates. It also can be used for food processing, leisure food production and ceramics production etc.Plate link belts are suitable for a wide range of active food contact applications such as:

l Baking

l Frying

l Drying

l Cooling

l Freezing

Specifications

- Material: carbon steel, SS 201, SS 304, SS 316.

- Plate thickness: 0.8 mm, 1 mm, 1.2 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm.

- Connection rod diameter: 5 mm, 6 mm, 8 mm, 10 mm, 12 mm.

- Rod pitch: 19.05 mm, 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 76.2 mm.

- Chain plate width: 200 mm to 4,000 mm.

- Belt length: according to customer's requirement .

- Surface treatment: hot dipped galvanized, blacking

Belt Types

|

|

|

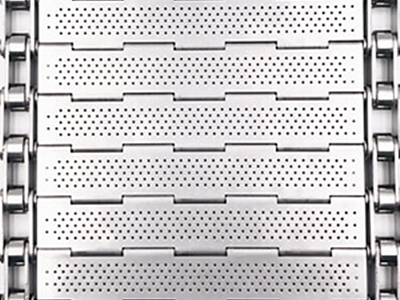

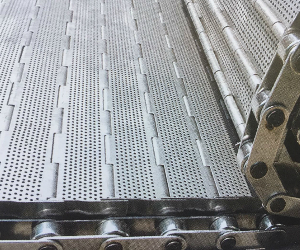

PCB01-Belt with perforations |

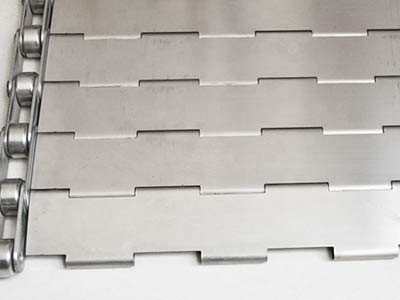

PCB02-Belt without perforations |

|

The holes supply excellent heat dissipation performance for conveying products. The holes can be made into different patterns and sizes. |

---------Flat plat conveyor belt, also called perforated non-perforated conveyor belt, which is the simple structure of metal plates. ----- |

|

|

|

|

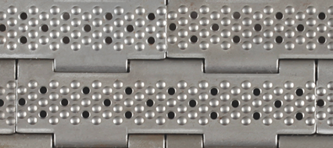

PCB03-Convex belt |

PCB04-Convex belt with perforations |

PCB05-Mesh belt |

|

Raised shapes avoid complete contact of the product with the belt surface, supplies anti-slip performance. |

This type of belt is suitable for that when small amount of liquid needs to be drained during transportation. |

This type of belt is suitable for when significant amount of liquid needs to be drained during transportation. |

Customization

Belt Without side plates and transverse baffle plate. ------------------------------------

Standard belt

Belt with side plates

Belt with transverse baffle plate

The side plates can be made into various designs and height to protect conveying products from falling down during elevation or decline.

The transverse baffles can make the sorting and conveying easy and convenient.

Transportation Forms

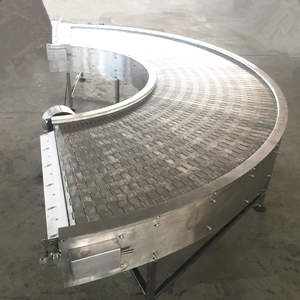

Metal chain plate conveyor belt can be made into direct transmission types, climbing types and turning types.

direct transmission types

climbing types

turning types

Support & Help Info

Our belts are designed for durabiliyty and optimal performance, making them ideal for a wide range of applications. As a leading manufacturer of plate link conveyor belts, with years of experience, advanced production techniques and a skilled team of professionals, we are able to provide top-notch plate link conveyor belts that are reliable, efficient, and cost-effective, and also provide our customers top-notch conveyor belt solutions.

Our commitment to innovation and continuous improvement has made us a trusted partner for businesses seeking a reliable conveyor solution. Choose us as your plate link conveyor belt manufacturer and experience the difference in quality and performance.

For all of your conveyor belt installation, commissioning, condition monitoring, and maintenance, please rest assured to contact us today!

Click Here To Watch Product Video

Request a Quote

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd