Stainless Steel SUS 304 Double Chain / Fruit Washing Conveyor Rust Resistant

Double Chain Wire Mesh Conveyor Belts

Introduction:

The Double Chain Conveyor Belt is a cutting-edge product that has revolutionized the field of material handling. With its innovative design and advanced features, this conveyor belt offers unparalleled efficiency and versatility. In this article, we will delve into the comprehensive product specifications, diverse applications, and noteworthy advantages of the Double Chain Conveyor Belt.

Product Specifications:

The Double Chain Conveyor Belt boasts the following specifications:

1. Belt Type: Wire Mesh Belt

2. Material: High-quality stainless steel

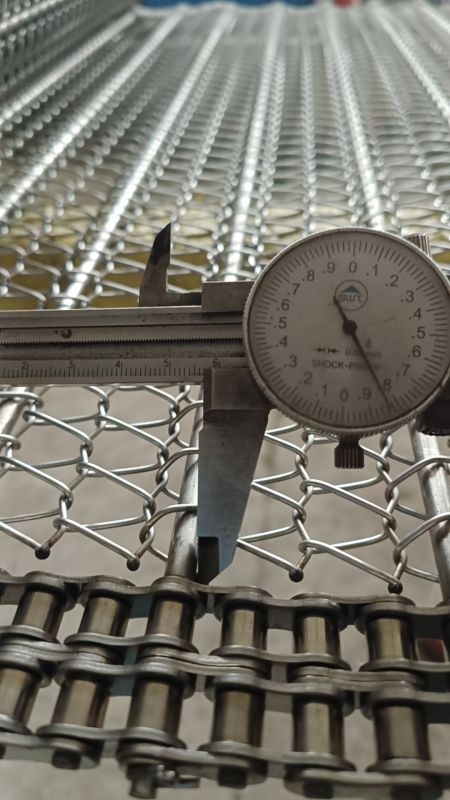

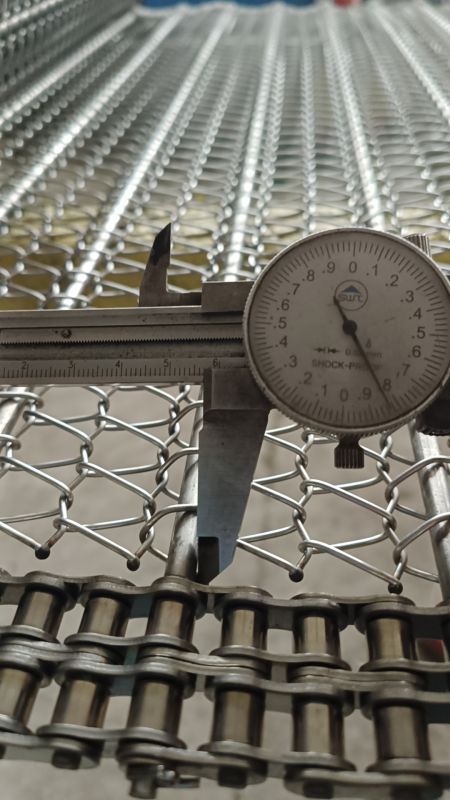

3. Chain Type: Double pitch roller chain

4. Belt Width: Available in various sizes, ranging from 12 inches to 60 inches

5. Load Capacity: Supports heavy-duty loads up to 2000 kilograms

6. Speed Control: Adjustable speed control for precise material handling

7. Drive Motors: Energy-efficient motors with variable frequency drive (VFD) for smooth operation

8. Safety Features: Equipped with emergency stop switches and overheat protection

Versatile Applications:

The Double Chain Conveyor Belt finds extensive usage in multiple industries, including but not limited to:

1. Automotive: Efficiently transports automotive parts along assembly lines, optimizing production efficiency.

2. Food Processing: Perfect for conveying food products during the manufacturing and packaging processes, ensuring hygiene and reducing manual labor.

3. Packaging: Facilitates the movement of packages or products in distribution centers, reducing handling time and increasing productivity.

4. Industrial Manufacturing: Transfers heavy components across different workstations for seamless workflow in manufacturing plants.

5. Warehousing: Enables quick and organized movement of goods within warehouses, reducing inventory management costs.

Key Advantages:

1. Enhanced Durability: Crafted from high-quality stainless steel, the Double Chain Conveyor Belt ensures robustness, making it suitable for heavy usage and challenging environments.

2. Superior Efficiency: The wire mesh belt design minimizes friction, resulting in smoother and faster material transfer, thus improving overall productivity.

3. Easy Maintenance: The belt's modular design allows for quick and hassle-free replacements, minimizing downtime and reducing maintenance costs.

4. Flexibility: The adjustable speed control and variable width options of the Double Chain Conveyor Belt make it adaptable to different production requirements.

5. Safety Assurance: The integrated safety features prioritize worker protection, ensuring safe operations and preventing accidents.

Conclusion:

With its impeccable design, versatile applications, and remarkable advantages, the Double Chain Conveyor Belt has become a game-changer in the realm of material handling. Its excellent performance, enhanced durability, and ease of maintenance have made it a preferred choice across diverse industries. Embrace innovation, streamline your operations, and revolutionize your material handling efficiency with the Double Chain Conveyor Belt.

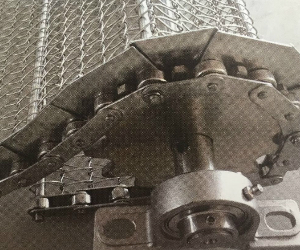

Unlike balanced weave belts, which consist of alternating left and right spiral coils, chain conveyor belts consist of unidirectional coils.For friction drive belts, the belt has alternating left and right sections.To counteract the tracking problems caused by the unidirectional coil pattern, cross bars are inserted into the belt - one is right-braided and the other is left-braided.

Features of RISEN's Conventional Mesh Belt:

• Simple structure. It is made of several spiral coils. Suitable for light-duty use in drying and cooling applications

• Economical. Economic and lightweight solution for low load conveying applications. The simple structure make it economical than other types of conveyor belt.

• Functional. The stainless steel Conventional Mesh Belt is suitable for lifting, conveying lightweight products.

• Different edge. We can supply welded or knuckled edge for your choice.

• Baffles are available. Side and center baffles can be added to the conveyor belt. Baffles can prevent the products from falling down to the ground. It is also useful for sorting and conveying.

• Chain link drive. The chain link drive pattern can ensure the smooth and high efficient working.

The Types of Belts:

1.Chain Link Belt Without Rod Reinforced

2.Chain Link Belt With Rod Reinforced

Because the cross rod passes through the interconnected helix, the rod-enhanced link belt is stronger than the traditional link belt.The rod not only increases the strength of the belt, but also makes the belt stable during delivery.

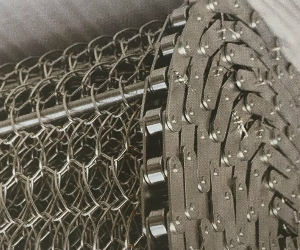

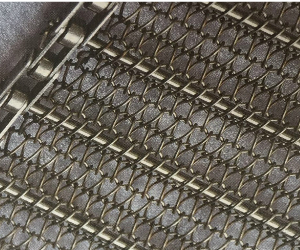

3.Chain Duplex Link Belt With Rod Reinforced

In addition to the standard rod reinforced chain belt, there are also rod reinforced double chain belt with double interwoven helix.This double-sided chain belt has a smaller opening area and greater strength.Compared with the general link belt, the rod reinforced link belt has the advantages of large bearing capacity, large opening area and low cost, so it has a wider application prospect.

Available Edges:

RISEN'S Chain Link conveyor belts come with different edge styles, including welded, hinged and chained.Other special edge treatments are available acoording to clients’ requirements.

1.Welded Edge:

At the edge of the belt, the coils are wound together and welded.This is the most common and economical edge treatment.This type of edge finish allows for a relatively smooth finish to the edge of the belt and is the most economical version of this belt style.

2.Knuckled Edge:

The end of each coil wire is bent backwards into a "U" shape and then interlocks with the adjacent coils.The "U" shape is then firmly closed to form a permanent connection with the next coil.This structure also allows for greater flexibility at the edge of the belt and minimizes the stress generated at these locations.

3.Chain Edge

As the mesh edges are completed, these meshes can be driven by side chains using cross bars that pass through the mesh coils and then through the chains at the mesh edges.

Available Materials of the Belts:

|

Materials |

Maximum Operating Temperature °C |

|

Carbon Steel |

550 |

|

Galvanised Mild Steel |

400 |

|

Chrome Molybdenum |

700 |

|

304 Stainless Steel |

750 |

|

321 Stainless Steel |

750 |

|

316 Stainless Steel |

800 |

|

316L Stainless Steel |

800 |

|

314 Stainless Steel |

1120 |

|

37/18 Nickel Chrome |

1120 |

|

80/20 Nickel Chrome |

1150 |

|

Inconel 600 |

1150 |

|

Inconel 601 |

1150 |

NOTED:We can be able to manufacture the belts according to your material requirements.

The Specification of Chain Link Belts without rod reinformed:

These are designed to meet customer requirements, but are generally available in 5.08mm to 25.4mm transverse coil wire pitch, combined with a variety of wire diameters and longitudinal pitch to suit the application.

A: Lateral Coil Pitch (mm) B: Longitudinal Coil Pitch (mm)

C: Wire Diameter (mm)

The Specification of Chain Link Belts with rod reinformed:

A: Lateral Coil Pitch (mm) B: Wire Diameter (mm)

C: Longitudinal Cross Wire Pitch (mm) D: Cross Wire Diameter (mm)

|

Specifications of Chain Link Belt With Rod Reinforced |

|||

|

Lateral Coil Pitch (mm) |

Wire Diameter (mm) |

Longitudinal Cross Wire Pitch (mm) |

Cross Wire Diameter (mm) |

|

16.93/15.24 |

2.03 to 4.06 |

16.93/19.05 |

2.03 to 4.06 |

NOTED:We can be able to manufacture the belts according to your material requirements.

The Specifications of Chain Duplex Link Belt With Rod Reinforced:

A: Lateral Coil Pitch (mm) B: Wire Diameter (mm)

C: Longitudinal Cross Wire Pitch (mm) D: Cross Wire Diameter (mm)

|

Specifications of Chain Duplex Link Belt With Rod Reinforced |

|||

|

Lateral Coil Pitch (mm) |

Wire Diameter (mm) |

Longitudinal Cross Wire Pitch (mm) |

Cross Wire Diameter (mm) |

|

16.93/15.24 |

2.03 to 4.06 |

16.93/19.05 |

2.03 to 4.06 |

NOTED:We can be able to manufacture the belts according to your material requirements.

Typical Applications:

● Annealing furnaces

● Cleaning machines

● Conveyor machines

● Drying ovens

● Frosters

● Frying facilities

● Ovens

● Refrigeration facilities

- Previous Product:Industrial Machinery Wire Mesh Belt

- Next Product:Double Chain Conveyor Belt

Get a Quote

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd