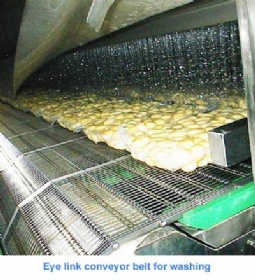

EyeLink Conveyor Belt with welded eye links

Eyelink Conveyor Belt for baking

Introduction:

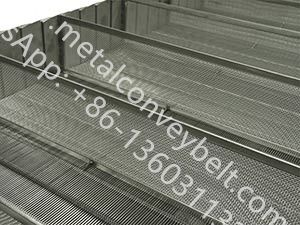

Eyelink Conveyor Belt for Baking is an innovative product designed to enhance the baking process by offering unparalleled performance, reliability, and versatility. This conveyor belt utilizes advanced technology and high-quality materials to meet the unique requirements of the baking industry. From its exceptional durability to its precise temperature control, Eyelink Conveyor Belt for Baking will undoubtedly elevate your baking operations to new heights.

Product Specifications:

1. Material: Our conveyor belt is made from premium-grade stainless steel, ensuring exceptional strength, corrosion resistance, and longevity.

2. Link Design: The unique eyelink design facilitates air circulation, resulting in even heat distribution and consistent baking results.

3. Belt Width and Length: Available in a range of customizable sizes to meet your specific baking needs.

4. Temperature Resistance: Operating temperature ranges from -100°C to 400°C, providing excellent thermal stability to withstand high-temperature baking environments.

5. Load Capacity: Designed to handle heavy loads while maintaining optimal performance and efficiency.

6. Cleaning and Maintenance: The open eyelink structure enables easy cleaning and maintenance, ensuring a hygienic baking environment.

The eyelink conveyor belt can provide multiple drive options, including friction driven cage rollers, forward drive sprockets, and optional chain edge drivers to enhance tracking and reliability. In addition, side shields and cross flight may be required. The design of the side panel is to control the height of the product to be transported.

Usage Scenarios:

1. Bakery Industry: Eyelink Conveyor Belt for Baking is perfectly suited for bakeries of all sizes, enabling efficient baking processes for bread, cookies, pastries, and more.

2. Food Production: Ideal for large-scale food production facilities where precise baking results and consistent quality control are crucial.

3. Industrial Ovens: This conveyor belt is compatible with various gas and electric ovens, making it highly versatile for different baking applications.

4. Pizza and Snack Chains: From conveyor belt ovens to cooling lines, our product offers flexible solutions for high-volume pizza and snack production.

Advantages Over Traditional Metal Mesh Belts:

1. Enhanced Precision: The eyelink design ensures accurate positioning and a reliable baking process, resulting in consistent product quality.

2. Improved Air Circulation: The open structure of eyelinks allows better air circulation, facilitating uniform heat distribution and thorough baking.

3. Higher Durability: Made from high-grade stainless steel, our conveyor belt offers exceptional resistance to wear, tear, and corrosion, ensuring a long lifespan.

4. Easy Maintenance: The open eyelink structure allows for effortless cleaning and prevents food particles from getting trapped, promoting hygiene and reducing downtime.

5. Customizability: Eyelink Conveyor Belt for Baking can be tailored to your specific requirements, including size, link design, and temperature resistance.

Types of Eyelink Conveyor Belts:

Eyelink conveyor belts - available in six types, each with specific advantages.

There are many types of eyelink conveyor belts from RISEN company, each with its own specific advantages, ranging from eyelink belts that compress to create the smallest possible opening, to eyelink belts with springs to ensure good seismic resistance and lateral force resistance.

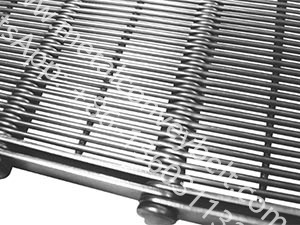

1.Full Eyelinks

For a full eyelinks, the eye links lean against each other, with openings equal to the wire diameter. It is designed and constructed without gaskets or vertically welded under the wires. This allows for excellent processes in applications that do not require cross support. Belts are commonly used in food processing due to their flat conveying surface, open mesh structure, and ease of cleaning. This type of eye chain conveyor belt without gaskets is also easy to repair at the lowest cost.

2.Pressed Eyelinks

Some applications require the smallest possible opening. By flattening the eyes of the eyelinks, the opening between the eye links becomes smaller. This type is very suitable for small and finely structured products.

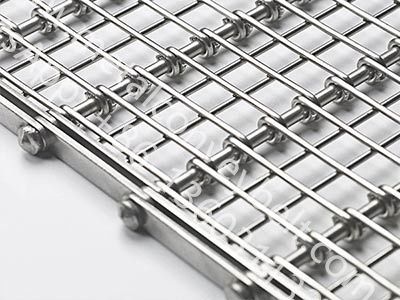

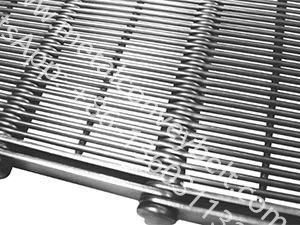

3.Welded Eyelinks

The eyelink is welded to a positioning line, forming a module. Very narrow and very wide openings can be created, depending on the processing of the product involved. The unwelded wire eliminates potential bacterial traps under isolation pads, springs, rings, and sleeves. This configuration makes cleaning and hygiene easier and more effective.

4.Pressed and Welded Eyelinks

Some applications require a stable belt and a small opening/discharge. The accuracy of our welding process enables us to produce very small spacing modules between eye chains. The modular structure makes it possible to assemble very wide belts.

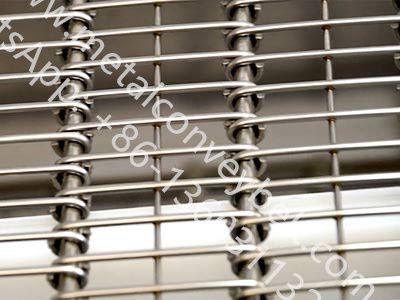

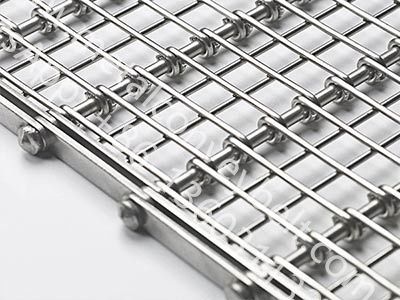

5.Eyelinks with Springs

Springs help create more stable size bands in heating or freezing applications. These belts have a more stable size as the wires can move on the cross pole. The spring also exposes a large portion of the connecting rod to improve cleaning and disinfection. The position of the springs between the eye chains ensures that they are positioned at fixed intervals. The result is a relatively lightweight belt with specific qualities such as good seismic resistance and lateral force resistance.

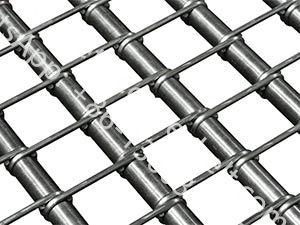

6.Eyelinks with bushings or washers

This versatile variable eyelinks belt uses bushings or washers between the wires to increase the gap of the belt. By increasing the belt gap, more air will circulate at the bottom of the product. Increasing product exposure to this additional airflow can improve your process efficiency. When adding liners or washers, the belt becomes heavier and more rigid.

Available Edge

1.Eyelinks Belt with Welded edge

2.Eyelinks Belt with Reinforcing Plates

3.Eyelinks Belt with Chain Edge

4.Eyelinks Belt with side Guards

Available Material:304 & 316 stainless steel, Carbon steel, other materials available based on request

Specifications:

A: Gap Width (mm) B: Pitch (mm)

C: Cross Rod Dia (mm) D: Underside Welded Wire Dia (mm)

E: Wire Link Dia (mm) F: Reinforcing Plate (mm)G: Overall Belt Width (mm)

|

Specifications of Eyelink Conveyor Belts |

||||||

|

A: Gap Width (mm) |

B:Pitch

(mm) |

C:Cross Rod Dia (mm) |

D:Underside Welded Wire (mm) |

E:Wire Link Dia (mm) |

F:Reinforcing Plate (mm) |

G:Overall Belt Width (mm) |

|

2 to 20 |

15.90 to 100 |

3 to 12 |

1 to 5 |

1.5 to 4 |

1.5 to 3 |

200 to 6000 |

NOTED: Custom specification is available if you can't find the suitable size.

Manufacturing Process:

Our Eyelink Conveyor Belt for Baking undergoes a meticulous manufacturing process that involves precision engineering, quality control measures, and extensive testing. Advanced machinery, combined with a highly skilled workforce, ensures that each conveyor belt meets the highest industry standards.

In conclusion, Eyelink Conveyor Belt for Baking is a game-changer in the baking industry, revolutionizing the way baked goods are produced. With its exceptional performance, durability, and versatility, this product provides unmatched precision, consistency, and efficiency in baking operations. Upgrade your baking process today with Eyelink Conveyor Belt for Baking and experience unparalleled results.

- Previous Product:EYE LINK WIRE BELT

- Next Product:EyeLink Conveyor Belt for baking

Get a Quote

Hebei Risen Conveyor Belt Products Co., Ltd

Hebei Risen Conveyor Belt Products Co., Ltd